In the magazine "Komfortní teplíčko", published by the Czech Pellet Cluster, an interview with our colleagues, Ing. Jakub Dohnal and Ing. Radek Machara.

Ing. Jakub Dohnal is a guarantor of wood pellets and EN Plus certification and has been working at SZU since 2016. He is also an inspector, auditor and certification specialist with a focus on pellets.

Ing. Radek Machara is a guarantor in the field of local heaters. He has been testing and certifying stoves and fireplaces since 2017.

Dohnal: Quality wood pellets for conventional domestic boilers and stoves come from clean, debarked wood. Such pellets produce only a small amount of ash, have a high calorific value and are environmentally friendly.The international ENplus certificate is used for easy orientation. The best quality pellets meet strict standards and carry the A1 mark.

Dohnal: ENplus certification guarantees that the pellets meet the standards not only for the technical parameters of the pellets, but also for the quality management system of the production. All certified manufacturers have their own laboratory where they test and analyse the correct set-up of the production process every day to ensure the highest quality of their pellets at all times.The correct set-up of the quality management system is checked every year by SZÚ staff during regular supervisory inspections.

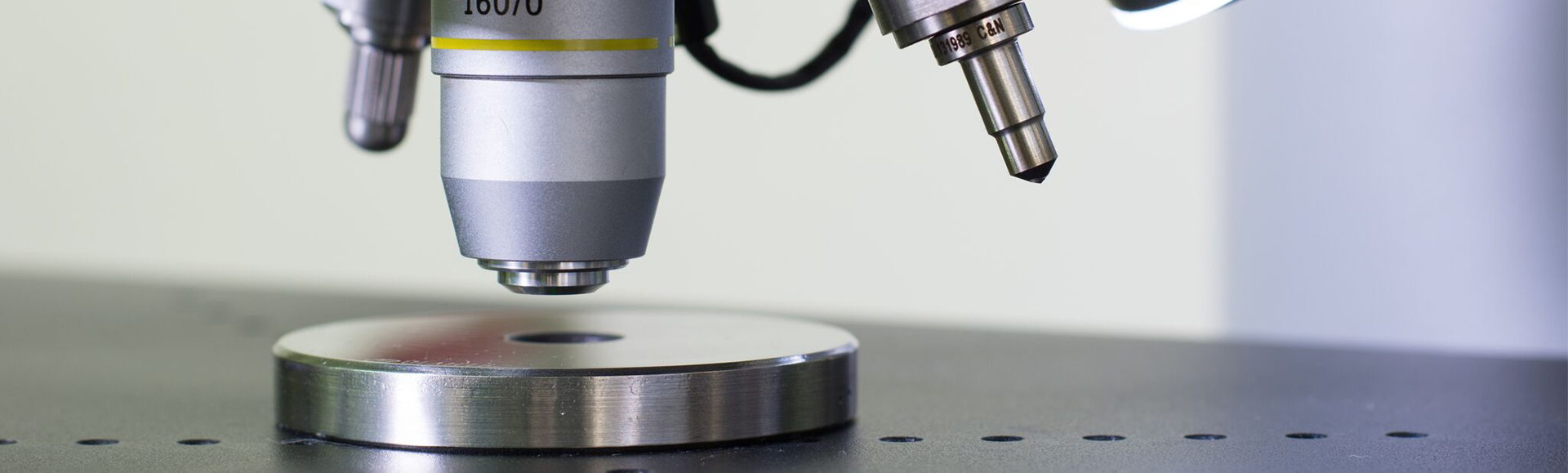

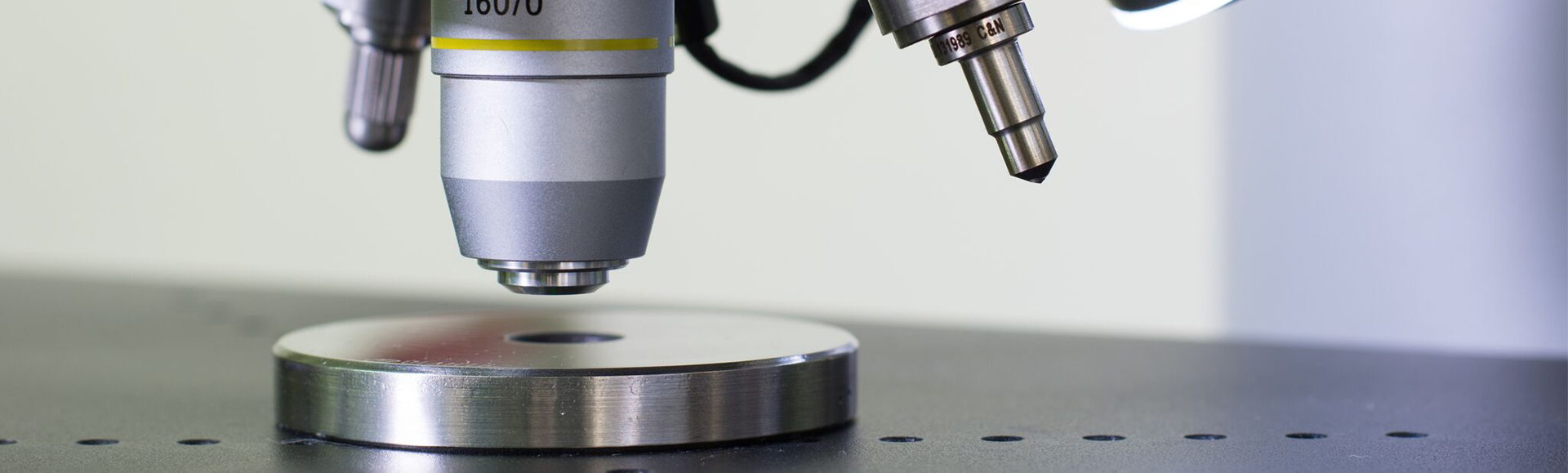

During an ENplus inspection, we take pellets from the production process and then analyse them in our accredited laboratory. Thanks to the comprehensive certification of ENplus by the Engineering Testing Institute (SZU), the end customer is assured of the highest quality pellets on the market!

Machara: Pellet stoves are rigorously tested for emission and performance parameters. A condition for placing pellets on the market is that they meet the requirements of the Ecodesign, i.e. strict emission limits and efficiency. In order to meet and consistently achieve the strict limits, it is necessary to use quality fuel, the quality of which is demonstrated by certification, which includes regular monitoring and verification of the quality of the pellets, as my colleague Dohnal said.

From our experience in pellet stove testing, the quality of the pellets plays a very important role. The results between certified and non-certified pellets vary by tens of percent in efficiency. This means that the user consumes tens of percent more fuel for the same performance (heat gained for heating).

Dohnal: These are mainly standards that are directly related to ENplus certification. We carry out tests according to these standards in our own accredited laboratory at SZU. Pellets of ENplus A1 quality have stricter requirements for the amount of ash and its fusibility and mechanical resistance compared to other quality classes.

Machara: EN 16510 Part 6 sets out the Ecodesign requirements and new testing methods and stricter requirements that equipment must meet.For example, the methodology for measuring fine dust particles during combustion has changed. This means that the worse the pellets, the worse the results and the higher the dust emissions to the surroundings (from the chimney).The use of uncertified, poor quality pellets, especially in the heating season, significantly affects the air quality in the surroundings. This is particularly unpleasant in built-up areas. Moreover, by using the wrong fuel, the user reduces the quality of his pellet stove.

Dohnal: The customer often makes a decision based on the colour of the pellets, but this certainly does not reveal the quality of the pellets as such. When pure shavings are used for production, the colour should logically be light.

A darker shade is caused by the material used and its moisture content when entering the production process. The colour will also be affected by the technology used in drying the raw material. The colour also changes during the pressing process due to the high pressure and temperature. The quality of the pellets is therefore not reflected in the colour.

Machara: For testing and the stove conformity assessment process, we only use certified ENPlus pellets, where we have guaranteed quality and stability. We verify their quality in our own chemical laboratory, which also tests samples for the pellet certifications we issue, as my colleague mentioned.

Machara: Yes, low-quality pellets produce more harmful substances that clog the combustion space and flueways. For example, due to the clogging, the stove may not recognize that there is imperfect combustion and may not properly evaluate the required fuel doses. For example, they can become clogged, risking dangerous conditions such as backfiring into the hopper.

Machara: Imperfect combustion results in higher ash and glass staining. This means that the user has to clean the combustion area and the glass more often.

Imperfect combustion also results in the aforementioned higher fuel consumption, the user has to refill the tank more often. Last but not least, the user will pay more per heating season for fuel with poor quality pellets than for certified pellets.

Dohnal: My colleagues and I test heating elements, floor convectors, ceiling panels and water heaters. These are products that no heating system can do without. At SZU, we also test and assess fittings used for heat and water distribution.

Machara: In addition to stoves and fireplaces, we also test solid fuel boilers. As you can see, the era of boilers of emission class 1 and 2 is coming to an end. These boilers should be replaced by new models that meet the stricter Ecodesign requirements.

Many Thanks to our colleagues J. Dohnal and R. Machara for the interview and the Czech Pellet Cluster "Klastr Česká peleta" for their excellent cooperation and publication of the article.

SZÚ team