In the latest interview with SZÚ Director Ing.Tomáš Hruska published in the prestigious magazine Reportáže z průmyslu (Reports from industry), you will get an insight into the key areas that shape our company and its future.

Tomáš Hruška shared the goals of the Strojírenský zkušební ústav (SZÚ) in the field of innovative technologies and sustainable energy solutions. He stressed the importance of continuous improvement and adaptation to new technological challenges.

He talked about how we plan to stay on the cutting edge of the industry and how we will continue to provide quality service to our clients.The interview provides insight into what we are doing, where we are going and how we are preparing for the future.

Be inspired by our commitment to innovation.

Also follow us on LinkedIn for more information and news here.

The activities of similar testing houses fall under the area called the TIC (testing, inspection, certification) sector. The TIC sector began to develop in England in the first half of the 19th century. It is thought to be related to the spread of steam engines, because when steam boilers were poorly designed, built or operated, they exploded with great damage to both property and lives. It is no coincidence that the first inspection institutions were initiated by the Lloyd's Insurance Company. But let us move from history to the present, to the Brno Engineering Testing Institute (SZÚ), headed by its director general, Tomáš Hruška. We talked to him about the current position of the company within our country and Europe.

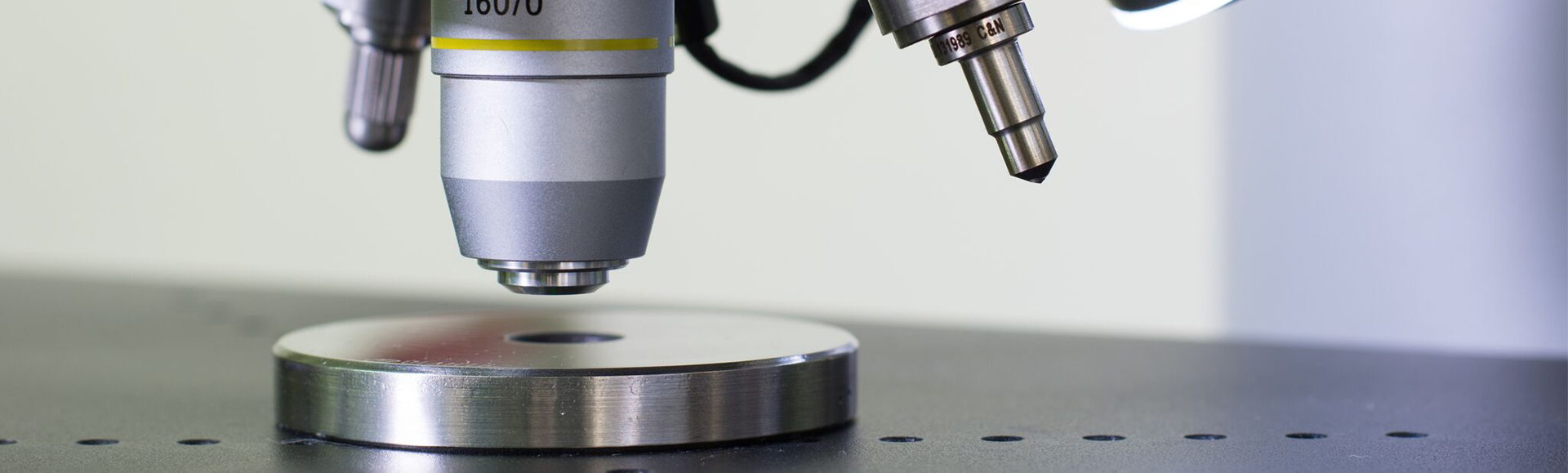

We test and certify a variety of products from small products, such as screws, to equipment in nuclear power plants. Manufacturers or operators as well as their end customers, we guarantee the following when conducting our tests objectivity, independence and credibility. It is therefore a typical commercial B2B service that combines technology, standards and legislation. We are active in all three areas, though mostly in testing. This is often followed by evaluation for product certification. We do not only certify products, but also management systems, such as ISO 9001, and also personnel. This means that we have accreditations for all of the above services mentioned above. We also offer a range of professional training and last but not least inspection services.

All products must comply with the relevant legislative regulations of the country in which you sell the products, so as a manufacturer you must always check what legislation applies to the product. There may be more than one piece of legislation. Our experts have an overview of Czech, European and international legislation.

Absolutely yes, it's one of our services. We are very well versed in legislation, and I mean worldwide, and we can advise you on how to start, what to follow and what parameters the product must meet in a given market.

A specialist can get to grips with the legislation. Big companies have a person or a whole department to do it, smaller companies may have a problem. But that's what we're here for. Europe is generally the most regulated region in the world, which has its disadvantages but also advantages. One of the advantages is that when any European manufacturer launches a product in the European Union, it may be sufficient for some other regions to launch that product there as well. Because they know how strict the European Union is.

Another aspect is product liability. Legislation forces the manufacturer to do a whole series of tasks, tests and certifications before they put it on the market. It then issues a declaration of conformity, and if there is an accident or even a fatality with the product, the manufacturer is covered if it has followed all the rules. In such cases, the vast majority of the time, the cause is human.

In North America or Canada, for example, there are not nearly as many legislative requirements, but you are responsible for the product. And then if something happens, in the vast majority of cases your company ends up in court, even if you can prove that the product complies with, for example, an American standard. It may well be that you will still be convicted on the grounds that you could have assumed that the standard was inadequate.

Probably like everyone in the last four years - a dysfunctional labour market, covid, the war in Ukraine, the energy crisis, inflation. In all of this, however, we have managed to carry out a major internal transformation of our company, i.e. an adjustment of the organisational structure that has not been touched since the 1980s, except for a few minor things. We have rebuilt the entire structure to optimise internal processes that affect our customers in particular. The aim was to ensure greater flexibility and efficiency.

Our teams are now divided by discipline, which better aligns with the corporate culture at SZU. The new organisational structure and the corporate culture support and reinforce each other and we are achieving better results. The success of the new organisational set-up in the company can only be evaluated after two years, but after the first six months, the change seems to be working well so far. One of the big drivers for it was the introduction of a new state-of-the-art ERP system, which was one of our first big projects and taught us a lot. Thanks to it, we then boldly went on to other major projects.

Hydrogen is gaining more and more attention as one of the ways to secure a more sustainable energy future. We have been actively involved in the use of hydrogen for several years in our combustion testing facility and currently offer testing and certification of gas appliances burning natural gas with hydrogen. This year we concluded a memorandum with our Korean partners in the field of hydrogen technology. The difference between the Czech Republic, Europe and Korea is that Korea has already resolved the issue of hydrogen use and they are going ahead with it. In my opinion, they have a big technical lead over Europe. They are looking at this pragmatically and in a businesslike way. They have chosen hydrogen to be one of the core energies that they will promote, and they already have dozens, if not hundreds, of hydrogen fuel cell applications to replace boiler plants. They also have a number of hydrogen energy appliance manufacturers and they want to export them to Europe. Photovoltaics are related to hydrogen because hydrogen can be used to store surplus energy. Logically, at SZU we try to offer services across a wide range of possible future energies.

In photovoltaics we have entered a completely new field. We cooperate with Brno University of Technology, specifically with the Faculty of Electrical Engineering and Communication Technologies and the Institute of Electrical Power Engineering. This April, we jointly opened a unique inverter compliance test facility, the very first accredited one in the Czech Republic. The development of testing and certification in the field of photovoltaics goes hand in hand with the change of legislation in the Czech Republic. Until now, manufacturers or distributors only needed to declare that the equipment is in order, now companies should have a certificate that confirms this.

An important technological and investment project of approximately forty million crowns was the construction of new climate chambers in which we test heat pumps. These chambers also enable noise measurements. We can adjust the air flow in the chambers, we can control the humidity in the chambers, as well as the temperature from about minus forty to plus sixty degrees Celsius. We have the chambers busy practically twenty-four hours a day, seven days a week. I am very happy about this successful project.

In the Czech Republic, we have testing facilities in two cities, abroad we have active sales offices in fourteen countries and we provide our services to customers in forty-three countries. Currently, more than sixty percent of our turnover comes from foreign orders. In some specific sectors

we are a European or world leader. These are mainly in the field of energy appliances such as heat pumps, fireplaces and wood stoves, where our know-how, historically passed down and further developed across generations of our employees, enables us to be a top partner for our customers. We enable manufacturing companies to develop and compete on their own. I am proud of our entire company and how far we have come in recent years.

We want to be Europe's leading testing, inspection and certification company, a stable partner for our customers and a sought-after employer. I see it as an important part of our company's mission that we help to build a safe world through our specific and highly professional activities. Previously we did not perceive how important the feeling of safety was for us, but the last years have brought many challenges and events that have shown us that safety cannot be taken for granted. Pandemics, political instability and cyber threats have confronted us with the fragility of our world. It is therefore essential that we now value more what we used to take for granted and actively seek to ensure security for ourselves and future generations. By verifying, evaluating, testing and then certifying products and services, we are saying, among other things, that they are safe. And in doing so, the HSE is doing its part to make everyone feel safe.