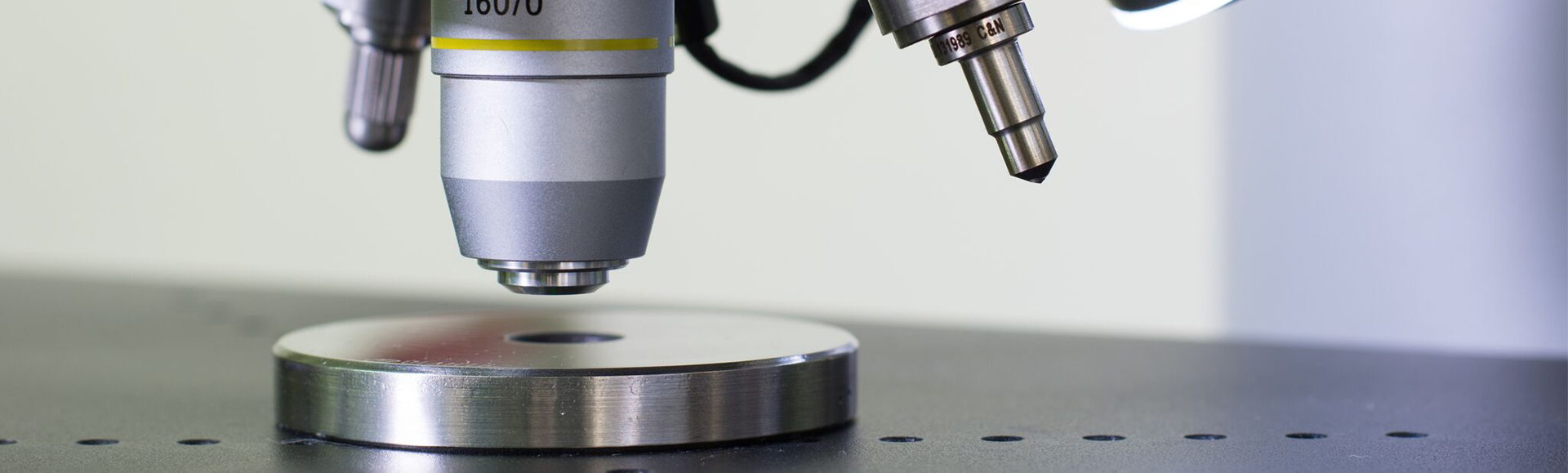

Corrosion resistance tests are performed in our laboratory in Jablonec nad Nisou on modern LIEBISH and QLAB chambers. The QLAB cyclic chamber can alternate the environment (NSS, condensed water, air, shower) and can be set to different temperatures and humidity levels according to customer requirements. The LIEBISH chamber is designed for NSS testing.

Volume of the test space: 1 100 dm3. The temperature range for these tests is 20°C to 70°C, humidity up to 100%. Chamber dimensions (l x w x h) = (1400 x 900 x 400) mm.

Tests may be carried out according to the procedures listed below:

Corrosion resistance in the fog of neutral sodium chloride solution by the NSS method (neutral salt spray) according to EN ISO 9227 and evaluation according to customer requirements. Chamber dimensions (l x w x h) = (1500 x 750 x 450) mm.

What is being assessed:

What is the output:

Accredited testing laboratory report with photo documentation and evaluation.

Why test:

Corrosion adversely affects the performance of products or equipment. Testing in corrosion chambers allows you to compare a test sample and a reference sample, or test samples, with each other and detect potential problems in manufacturing or coating.

Corrosion testing has a wide range of applications in the engineering, automotive, aerospace, construction etc. industries as it can assist in the selection of materials, components and surface treatments to ensure optimum service life.

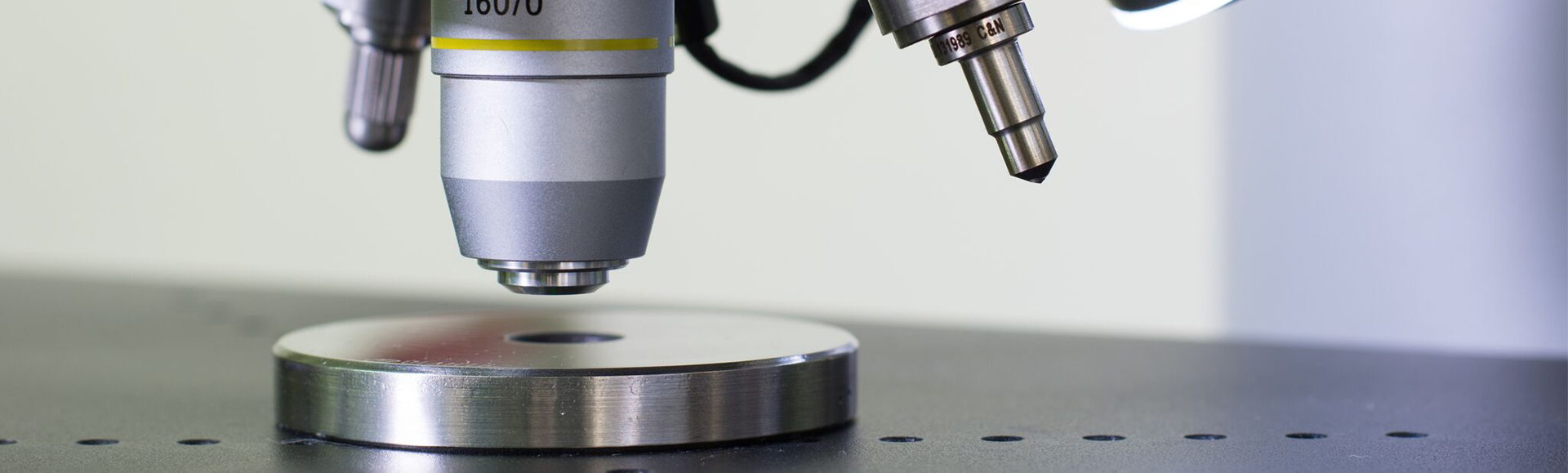

We perform tests in our modern QLAB UV chamber.

Our chamber uses UVA 340+ lamps and it is possible to perform tests of paints, plastics and textiles.

Tests are performed according to the standards:

What is output:

Protocol from the accredited testing laboratory with photo documentation and evaluation.

Why test:

UV radiation simulates and accelerates the aging of materials. This test method can show changes in the properties of materials that occur when exposed to UV radiation. Changes that occur can be: discoloration, loss of light, cracking, blistering, brittleness, loss of strength, and oxidation. These changes affect appearance, performance, and durability. UV radiation can be used to find design and material defects. It can also predict the durability of products.

Fasteners, Material and Corrosion Tests Specialist

stepan@szutest.cz

+420 483 348 221

+420 727 947 750

1.

Inquiry

If you are interested in any of our services, please contact us.

2.

Specification

Our experts will contact you soon and specify the details of your inquiry.

3.

Offer

After clarifying the details we will prepare a final offer for you.

4.

Order

You will then fill in a binding order.

5.

realization

After signing the contract, we will start to execute your order.